Digital Bevel Angle Indicator for Bench Grinders

Digital IsoBevel Mk. III, US Pat. No. 6,848,971

For centuries, the grinding wheel has been an essential element of almost every woodworking and metalworking shop in the world. This simple device, like most tools has evolved with the technology of the times. It is therefore surprising that the modern bench grinder has not benefited from the enhancements that the information age has brought to many other tools and appliances. This device offers a digital solution to the problem of setting a bench grinder toolrest to accurately control the bevel angle that will be ground on tool or workpiece.

In the past, accurately and consistently setting a grinder's toolrest to obtain a desired bevel angle on a tool has been a time consuming and frustrating process because bevel angle scales were either nonexistent or inaccurate. By taking advantage of inexpensive state-of-the art programmable micro-controller technology, it is now possible to bring this capability to a wide range of users.

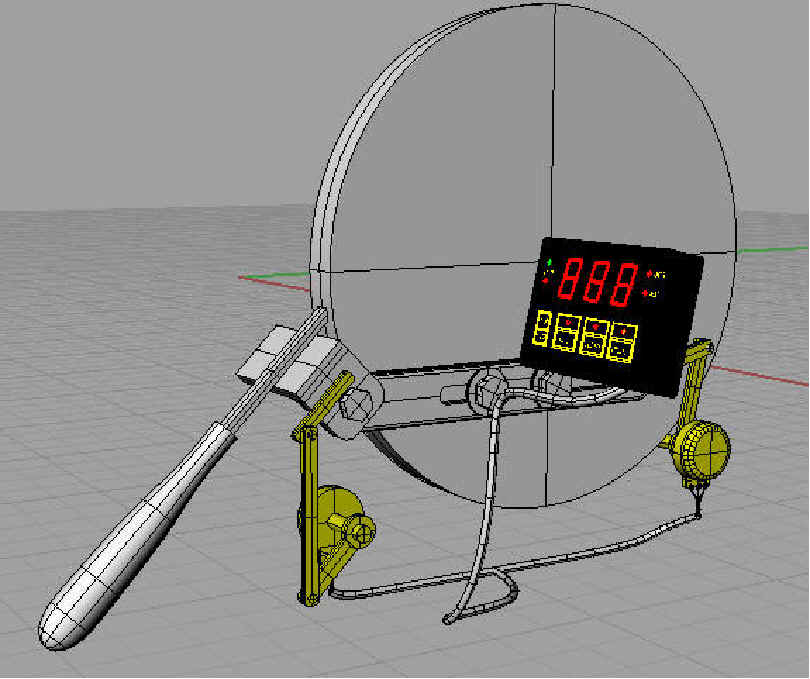

This prototype of a digital bevel angle indicator demonstrates the capabilities that modern technology can bring to a typical bench grinder. The user, simply manipulates the toolrest using the normal adjustment features of the bench grinder, while the bevel angle that will be ground on the tool or workpiece is displayed to the user by a digital display. With the simple push of a button, the device tracks angle adjustments on either the left or right wheel. The user interface also allows the user to ensure that the indicator maintains accuracy as the grinding wheels wear.

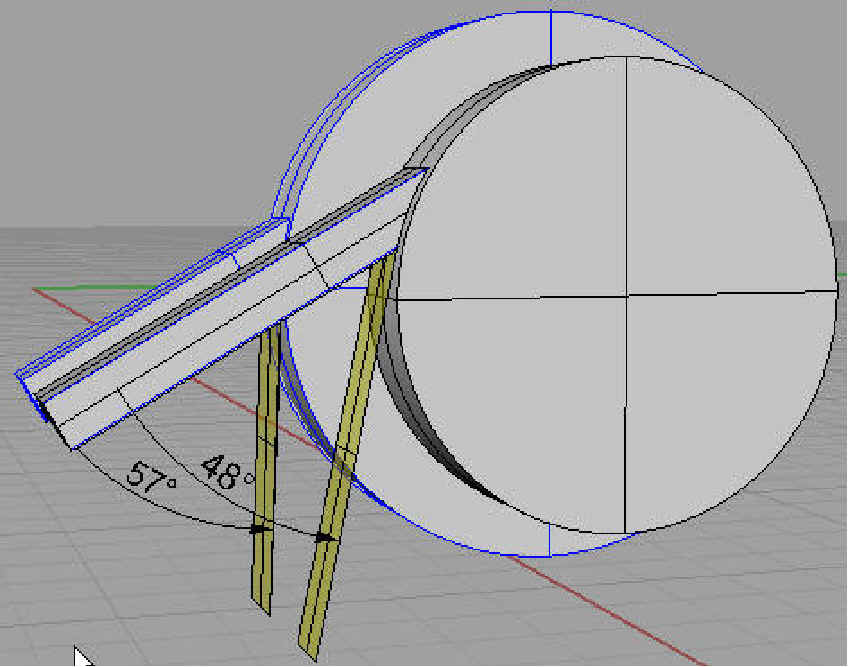

Changes in the wheel diameter change the parameters in the mathematical relationship between the toolrest position and the bevel angle. This explains why angle indicator scales on conventional grinders, when they do exist, are only accurate when the grinding wheel is new. To illustrate, this model shows two workpieces held in identical positions relative to the center of the grinding wheel. One can see that the orientation of the yellow tangent planes to the wheels are different; thereby showing that wheel diameter can dramatically influence the bevel angle that will be ground on the tool.

The variables affecting the bevel angle include not only wheel diameter but also linear and angular adjustments of the toolrest. By mounting toolrest position sensors, which are highlighted in yellow on the model, one can obtain the measurements that are required to calculate the bevel angle that will be ground on the tool when it is placed flat on the surface of the toolrest.

A microcontroller chip processes these sensor measurements and uses an equation to compute and display the bevel angle to the user.

The prototype circuitry was created by hand on a brass-board and is therefore much larger than a production unit. Production units would take advantage of printed circuit boards and surface mount components. The total retail cost of the components for the prototype unit was under 25 dollars. The cost of production units would be much less due to economies of scale.

Links:

US Pat. No. 6,848,971 in PDF Format

Copyright © 2003-2007 David B. Doman, PhD All rights reserved.